Smart Factory Modeling and Simulation

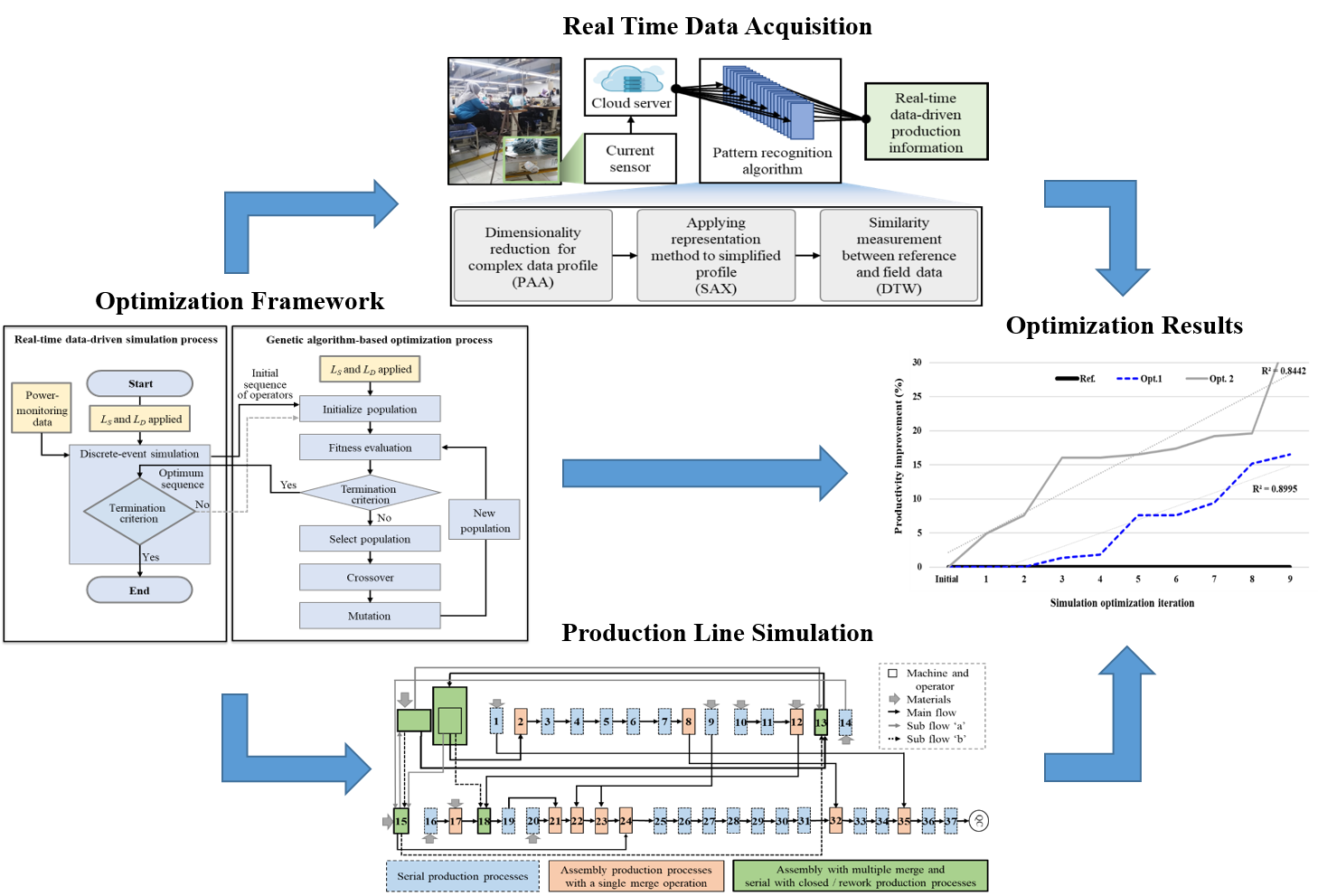

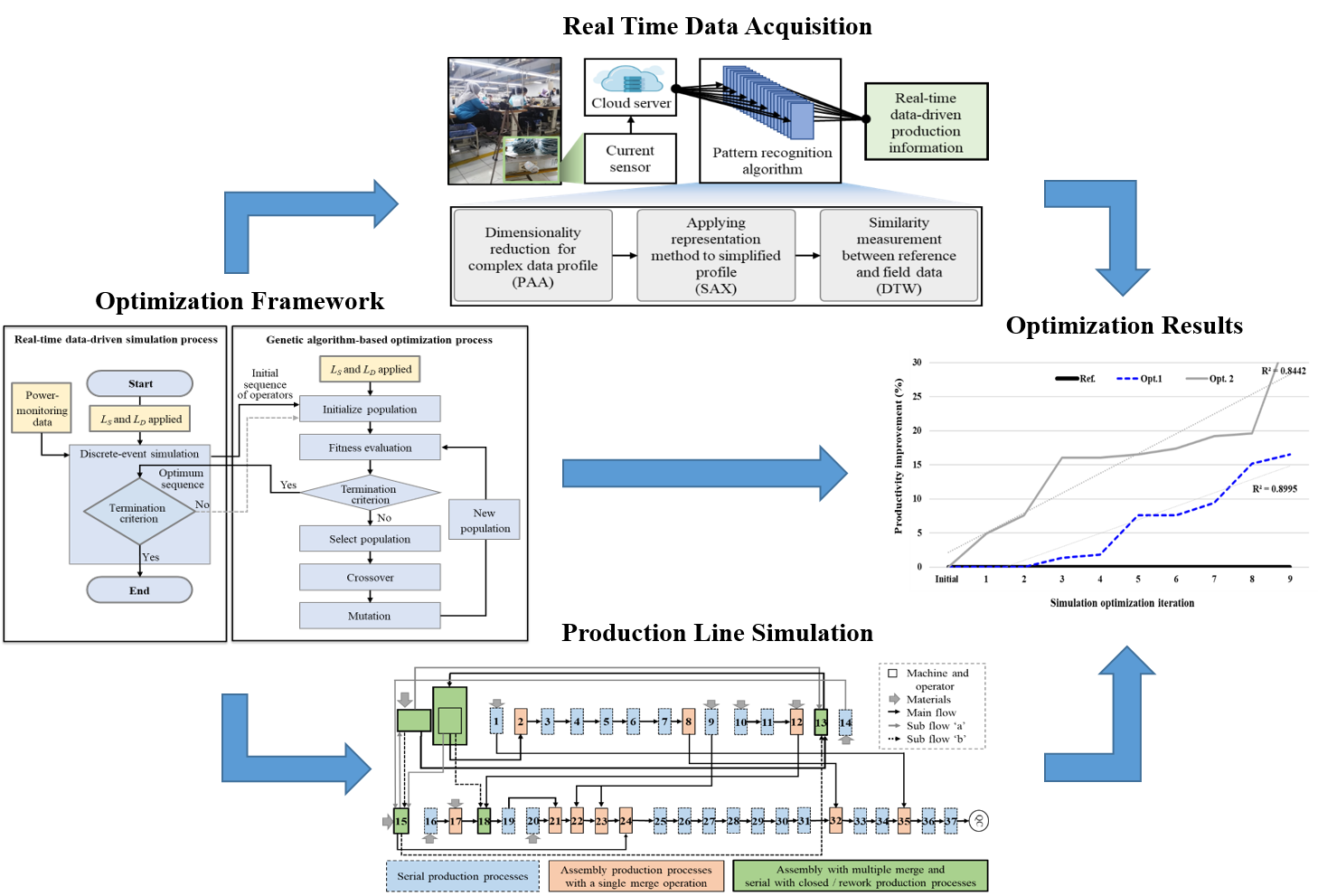

Smart factory has become a key term in the manufacturing industry, with many companies in various industries trying to define and implement their vision of smart factories. Our research effort in this area focused on smart factory technology implementation for labor-intensive garment factory to improve the overall productivity. Following figure shows the overall vision of our research.

In labor-intensive environment such as a garment factory shown, each worker's work pace vary, and this leads to unwanted productivity loss. To improve the ovearll productivity, we have designed a framework to accurately measure each worker's takt time in real-time, and use the acquired data to optimize the overall production line. Following figure shows the overall modeling and optimization framework.

We implemented power monitoring system for sewing machine to each working station, measuring and analyzing sewing pattern for each garment assembly process in real time. Acquired data was used as inputs into discrete-event simulation model of the assembly line, yielding various productivity measures. These results are used as inputs to an optimization module, yielding improved results for the overall assembly worker placement to improve the overall productivity. This framework has been implemented in an actual garment factory in Indonesia with success.

In labor-intensive environment such as a garment factory shown, each worker's work pace vary, and this leads to unwanted productivity loss. To improve the ovearll productivity, we have designed a framework to accurately measure each worker's takt time in real-time, and use the acquired data to optimize the overall production line. Following figure shows the overall modeling and optimization framework.

We implemented power monitoring system for sewing machine to each working station, measuring and analyzing sewing pattern for each garment assembly process in real time. Acquired data was used as inputs into discrete-event simulation model of the assembly line, yielding various productivity measures. These results are used as inputs to an optimization module, yielding improved results for the overall assembly worker placement to improve the overall productivity. This framework has been implemented in an actual garment factory in Indonesia with success.

Related Papers